Description

Profile

The corrosion resistance of XM-19 stainless steel is excellent. Due to its high content of chromium and nickel, this stainless steel has good self-protection properties and can maintain stable performance in various corrosive environments. XM-19 stainless steel also has very good heat resistance. It can maintain stable performance in high temperature environments and is not prone to oxidation and deformation.

Therefore, XM-19 stainless steel is widely used in various high temperature and thermal environments. ASTM XM-19 stainless steel also has good processing properties and welding properties. Lastly, this stainless steel can be processed into a variety of complex shapes and sizes, and has good welding properties to meet various manufacturing and processing needs.

Product Description

|

Product |

XM-19 Stainless Steel Plate |

|

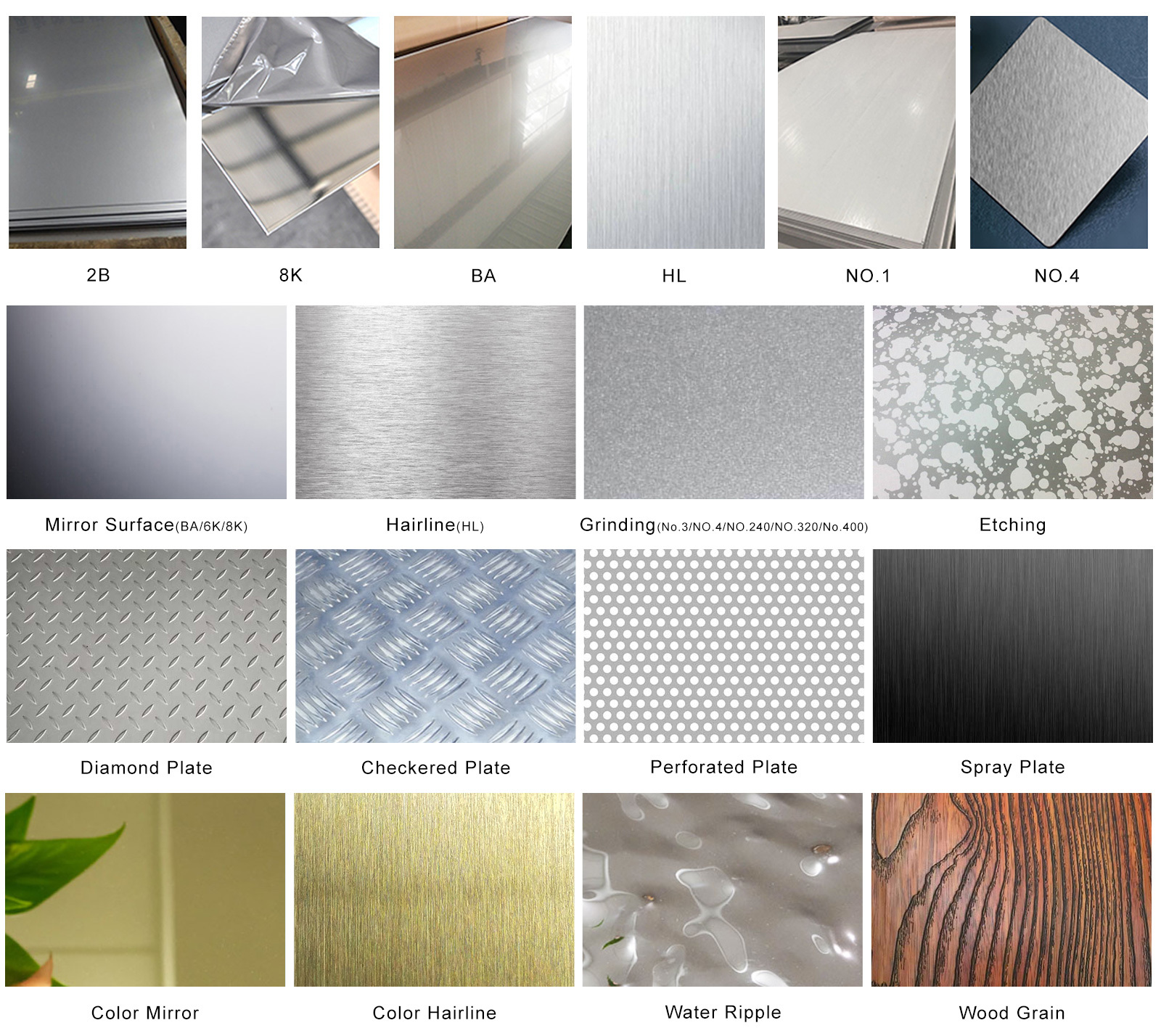

Surface Finish |

BA, 2B, 4K, 6K, 8K, NO.4, HL, Embossed, Perforated, Pickling white, Polished outside, Polished inside and outside |

|

Technique |

Hot Rolled / Cold Rolled |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc |

|

Width |

500mm/1000mm/1219mm/1250mm/1500mm/1800mm/2000mm/2200mm/2500mm/3000mm/3500mm, or as required |

|

Length |

500mm/1000mm/2000mm/2438mm/2500mm/3000mm/6000mm/8000mm—13000mm, or as required |

|

Thickness |

0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.2/1.5/2.0/2.5/3.0/4.0/5.0/6.0/8.0/10.0/12.0/14.0/16.0—250mm, or as required |

|

Material |

201, 202 |

|

Color |

Standard RAL color: Red, Blue, White, Grey, Brick, etc. |

|

Stock Dimension |

Cold Rolled: 0.4-6.0mm*1000*2000mm/ 1220*2440mm/ 1250*2500mm/ 1500*3000mm, or as your request |

|

Service |

OEM, Customized processing service, Customized fabrication by drawings |

|

Processing Type |

Cutting, Bending, Stamping, Welding, CNC machining |

|

Cutting Type |

Laser cutting; Water-jet cutting; Flame cutting |

|

Protection |

1. Inter paper available |

|

Application |

Costruction Industry/ Kichten Products/ Fabrication Industry/ Home Decoration |

Chemical Composition

|

C |

Mn | Si |

Cr |

Ni | Mo | N | Nb | V | P |

S |

|

≤ 0.06 |

4.0~6.0 | ≤ 1.0 |

20.5~23.5 |

11.5~13.5 | 1.5~3.0 | 0.2~0.4 | 0.1~0.3 | 0.1~0.3 | ≤ 0.04 |

≤ 0.03 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥500 |

≥1180 |

≥40 |

≤ 180HB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.78 |

200 |

10.0 |

14.0 |

0.6 |

Surface Selection

Reviews

There are no reviews yet.