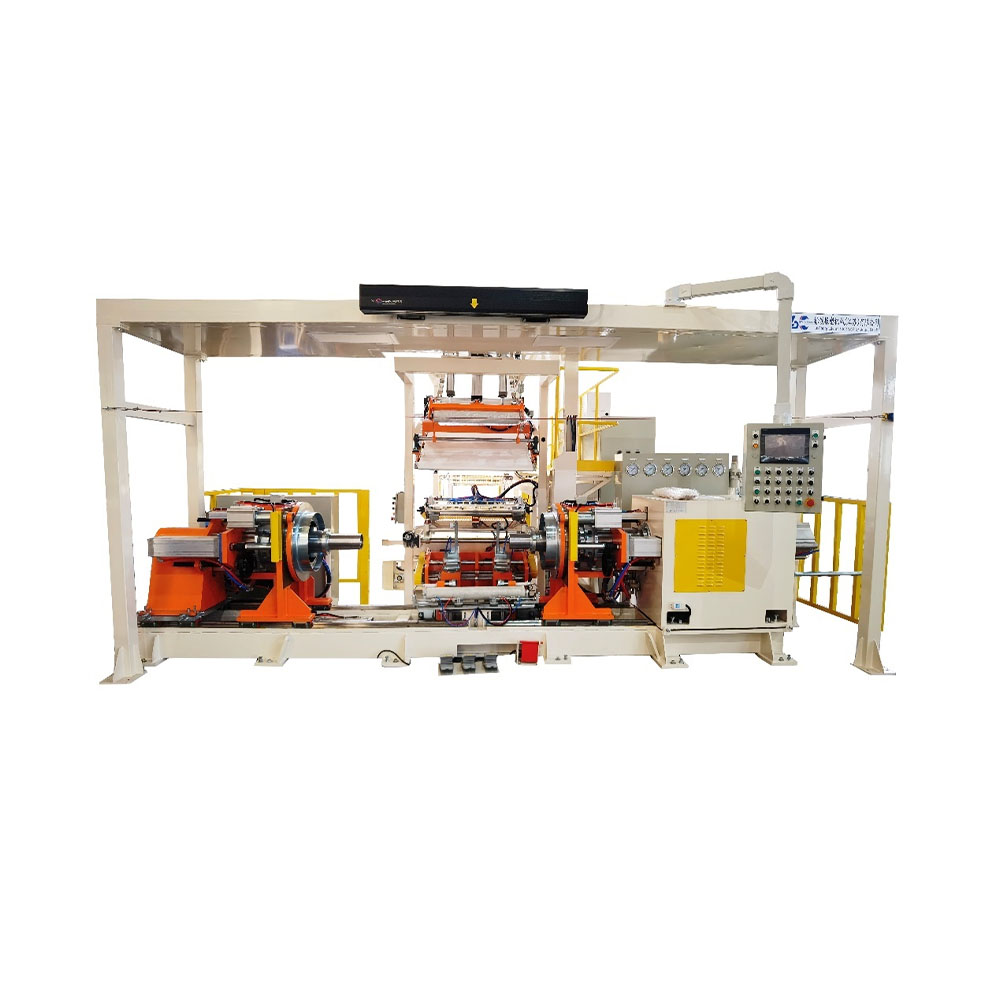

Description

Product Features:

● Suitable for the production of HP/UHP/SUV/MT/AT tires

● Adapt to three production modes

① Single-layer mode

② Inner liner and 1# cord composite mode

③ Inner liner and 1#, 2# cord composite mode

● Optional MITSUBISHI/SIEMENS/AB control system

● Automatic deviation correction, pre-cutting, automatic forming drum loading for inner liner/cord feeder

● Rear pressure roller/lower pressure roller are both servo-controlled, with high pressure accuracy and stability

● Automatic lamination and cutting on drum

● Automatic sidewall lamination and automatic drum loading

Equipment Parameters:

|

Items |

Parameters |

|

Tire specifications |

10″~16″ (14″ -18″, 17″ -21″) |

|

Sidewall width |

60-250mm |

|

Maximum outer spacing between two sidewalls |

580mm |

|

Minimum inner spacing between two sidewalls |

80mm |

|

Sidewall cutting angle |

35°~45° |

|

Liner roll form |

Trolley |

|

Liner roll diameter |

Max450mm |

|

Liner width |

300-900 mm |

|

Liner cutting angle |

35° |

|

1# 2# cord roll form |

Trolley |

|

1# carcass cord width |

Max1000 |

|

2# carcass cord width |

Max1000 |

|

Cord cutting angle |

0° |

|

Green tire outer diameter |

460-850mm |

|

Main machine center height |

850-900mm |

|

Cord single side extending out of drum |

≤150mm |

|

Drum diameter range |

φ390-φ471mm |

|

Drum tile number |

≥8 pieces |

|

Drum width |

240-560mm |

|

Drum speed |

35-250rpm |

|

Apex height (including wire ring) |

Max70mm |

|

Apex thickness range |

5-15mm |

|

Cutting method |

Drum fixed length hot knife |

Equipment Accuracy:

|

No. |

Item |

Parameters |

|

|

1 |

Lining |

Cut slope |

≤40° |

|

2 |

Joint quantity |

4±1mm |

|

|

3 |

Cutting fixed length |

±1mm |

|

|

4 |

Centering |

±1mm |

|

|

5 |

1# carcass cord 2# carcass cord |

Cutting angle |

0° |

|

6 |

Joint quantity |

4±1CORD |

|

|

7 |

Cutting fixed length |

±1mm |

|

|

8 |

Centering |

±1mm |

|

|

9 |

Sidewall |

Cutting angle |

≤40° |

|

10 |

Joint quantity |

对接 |

|

|

11 |

Cutting fixed length |

±1mm |

|

|

12 |

Centering |

±1mm |

|

|

13 |

Material stretching |

Material stretching |

≤1.0mm |

|

14 |

Overall horizontality of the main machine |

±0.04mm/1000mm |

|

|

15 |

Spindle circular runout |

≤0.05mm |

|

|

16 |

Center beam width |

≤0.5mm |

|

|

17 |

Center beam position accuracy |

SPEC±0.5mm |

|

|

18 |

BEAD loading circle circular runout |

≤0.20mm |

|

|

19 |

BEAD loading circle verticality |

≤0.20mm |

|

|

20 |

Lower pressure roller centering |

±0.5mm |

|

|

21 |

Rear pressure roller centering |

±1.0mm |

|

|

22 |

Feeder rack horizontality |

± 0.5mm/m |

|

|

23 |

Feeder rack verticality |

± 0.5mm/m |

|

|

24 |

Forming machine head positioning accuracy |

≤ ±1° |

|

|

25 |

Joint distribution angle error |

≤ ±1° |

|

|

26 |

Spindle to tailstock coaxiality |

≤0.15mm |

|

|

27 |

Spindle to tailstock end face runout |

≤0.20mm |

|

Reviews

There are no reviews yet.