Description

https://www.magicmag-tech.com/Fixed-Speed-Basic-Model-Cylinder-Type-FBM-C-Magnetic-Coupling.html

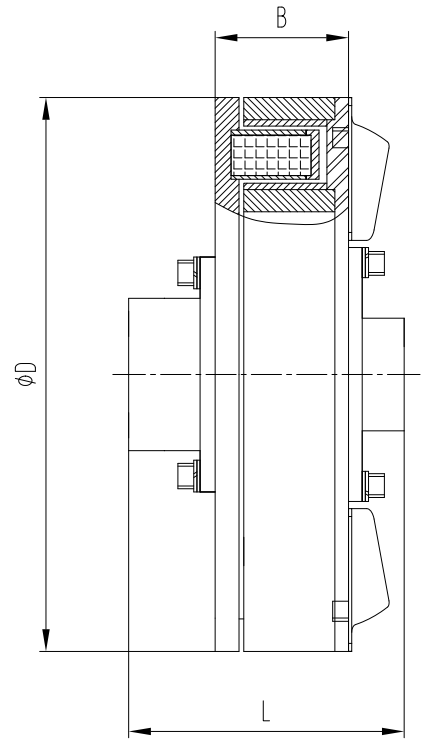

STRUCTURAL PATTERN

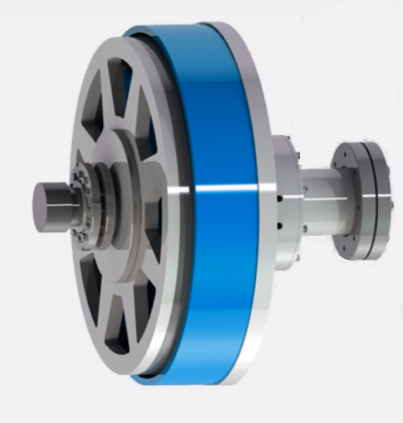

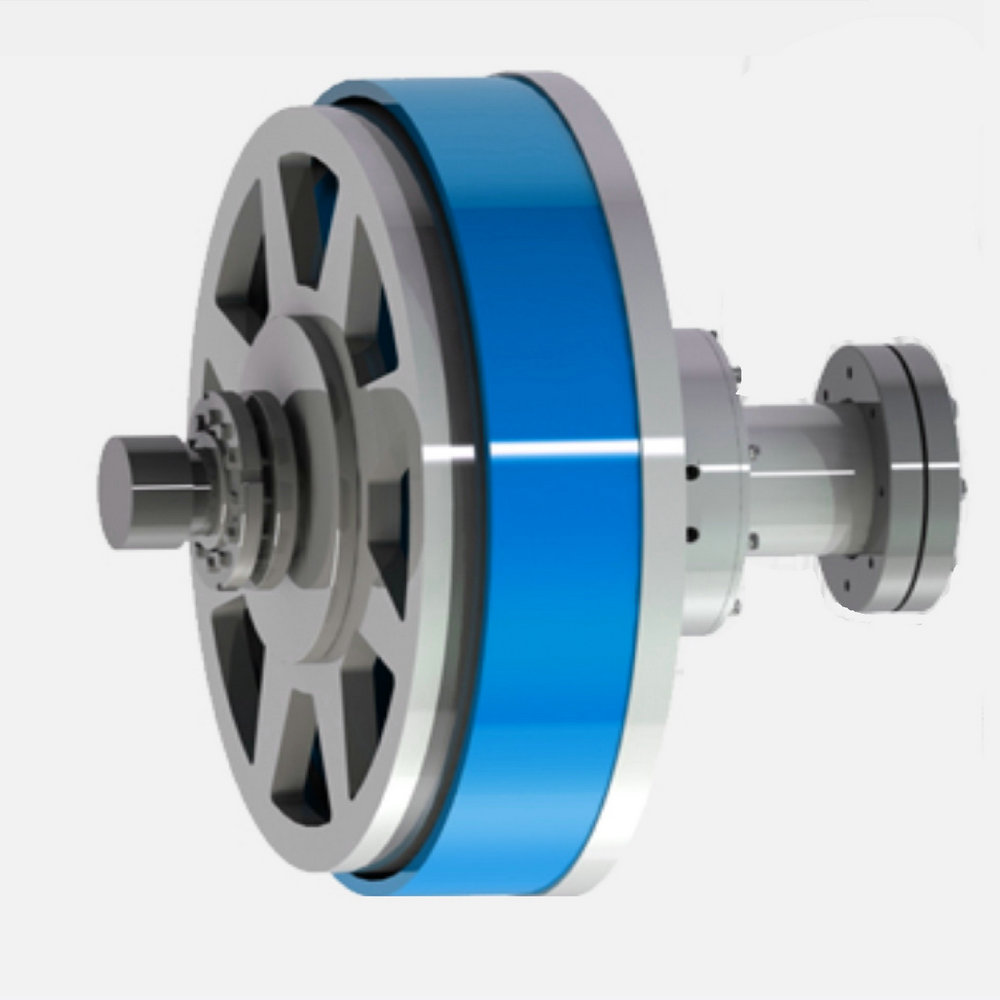

PRODUCT DESCRIPTION

An FBM(C) consists of two separate components that have no physical contact. It is mounted in a round cylinder with a powerful permanent magnet rare earth magnet。A conductor consisting of a steel housing with copper rings mounts on the other shaft. The coupling’s ability to transmit torque is created by the relative motion between the copper conductor and the magnets. This motion creates a magnetic field in the copper that interacts with the permanent magnets, thus transmitting torque across the air gap.

● Special cylinder structure, can meet the high-power transmission equipment

● Air gap between magnetic rotor (driven side) and conductor (driver side) reduces vibration

● Copper conductor design maximizes induction of magnetic fields

● Steel plates focus magnetic flux through copper conductors to maximize magnetic fields

● Coupling is designed to minimize ElectroMagnetic Interference (EMI) –flux level lower than associated motor

RANGE OF APPLICATIONS

MagicMACTM products are used with a wide variety of rotating equipment in industry. The top twelve applications of MagicMACTM technology are as follows:

● Pumps

● Blowers

● Conveyors

● Fans

● Clinker Grinders

● Bucket wheels

● Air Pre-heaters

● Re-Pulpers

● Centrifuges

● Crushers

● Compressors

● Bucket Elevator

And many more…

SPECIFICATION

|

Model |

Input Speed/ number of poles |

Rotating Power (kw) |

External dimensions |

Maximum Input Speed (r/min) |

Weight. (kg) |

|

|

Diameter (mm) |

Width (mm) |

|||||

|

FBM-A0011-04C |

1500/4 |

11 |

349 |

84 |

3000 |

29 |

|

FBM-A0015-04C |

1500/4 |

15 |

349 |

84 |

29 |

|

|

FBM-A0018-04C |

1500/4 |

18.5 |

349 |

84 |

29 |

|

|

FBM-A0022-04C |

1500/4 |

22 |

349 |

84 |

29 |

|

|

FBM-A0030-04C |

1500/4 |

30 |

460 |

156 |

73.6 |

|

|

FBM-A0037-04C |

1500/4 |

37 |

460 |

156 |

75.3 |

|

|

FBM-A0045-04C |

1500/4 |

45 |

460 |

156 |

77 |

|

|

FBM-A0055-04C |

1500/4 |

55 |

460 |

156 |

78.7 |

|

|

FBM-A0075-04C |

1500/4 |

75 |

460 |

156 |

80.4 |

|

|

FBM-A0090-04C |

1500/4 |

90 |

460 |

156 |

82 |

|

|

FBM-A0110-04C |

1500/4 |

110 |

597 |

156 |

99.72 |

|

|

FBM-A0132-04C |

1500/4 |

132 |

597 |

156 |

101.42 |

|

|

FBM-A0160-04C |

1500/4 |

160 |

597 |

156 |

103.11 |

|

|

FBM-A0185-04C |

1500/4 |

185 |

597 |

156 |

104.8 |

|

|

FBM-A0200-04C |

1500/4 |

200 |

597 |

156 |

106.5 |

|

|

FBM-A0220-04C |

1500/4 |

220 |

725 |

190 |

173.8 |

|

|

FBM-A0250-04C |

1500/4 |

250 |

725 |

190 |

177 |

|

|

FBM-A0280-04C |

1500/4 |

280 |

725 |

190 |

180 |

|

|

FBM-A0315-04C |

1500/4 |

315 |

725 |

190 |

183 |

|

|

FBM-A0355-04C |

1500/4 |

355 |

725 |

190 |

186 |

|

|

FBM-A0400-04C |

1500/4 |

400 |

725 |

190 |

189 |

|

|

FBM-A0450-04C |

1500/4 |

450 |

725 |

190 |

192 |

|

|

FBM-A0500-04C |

1500/4 |

500 |

725 |

190 |

237.4 |

|

|

FBM-A0630-04C |

1500/4 |

630 |

850 |

205 |

240 |

|

|

FBM-A0710-04C |

1500/4 |

710 |

850 |

205 |

1500 |

243.4 |

|

FBM-A0800-04C |

1500/4 |

800 |

850 |

205 |

246.5 |

|

|

FBM-A0900-04C |

1500/4 |

900 |

1022 |

210 |

286 |

|

|

FBM-A1800-04C |

1500/4 |

1800 |

1022 |

210 |

480 |

|

FAQ

Q1: What is the Fixed Speed Basic Model Cylinder Type (FBM-C) Magnetic Coupling?

A1: The Fixed Speed Basic Model Cylinder Type (FBM-C) Magnetic Coupling is a specialized magnetic coupling designed for high-power and high-reliability transmission applications. It features a unique cylindrical structure, which allows for efficient torque transmission and excellent misalignment tolerance. This coupling is ideal for industrial equipment that requires high power, high reliability, and compact installation space.

A rodless cylinder magnetic coupling is a type of pneumatic actuator that uses magnetic force to connect the internal piston to an external slider. Unlike traditional cylinders with protruding rods, this design eliminates the need for a physical rod, allowing for a more compact and sealed structure.

Q2: What are the key features of the cylinder magnetic coupling?

A2: The key features of the cylinder magnetic coupling include:

Cylindrical Structure: The unique cylindrical design provides higher torque transmission capability and compact installation space.

High Misalignment Tolerance: It can accept significant axial and radial misalignments, reducing alignment requirements during installation and operation.

Low Maintenance Cost: Designed for a lifespan of up to 30 years with minimal maintenance required.

Energy-Efficient: Optimized magnetic design reduces energy loss and improves system efficiency.

Q3: What is the specification scope of the cylinder magnetic coupling?

A3: The specification scope of the cylinder magnetic coupling includes:

Power Range: From 15 kW to 1800 kW, suitable for medium to high-power equipment.

Motor Compatibility: Designed for use with 1500 r/min, 4-pole motors.

Q4: How does the Fixed Speed Basic Model Cylinder Type Magnetic Coupling reduce system vibration?

A4: The Fixed Speed Basic Model Cylinder Type Magnetic Coupling reduces system vibration through its unique design. The air gap between the magnetic rotor (driven side) and the conductor (driver side) helps to minimize vibrations. Additionally, the steel plates focus the magnetic flux through the copper conductors, maximizing the magnetic fields and ensuring smooth torque transmission.

Q5: What is the maximum input speed for the cylinder magnetic coupling?

A5: The maximum input speed for the cylinder magnetic coupling is 3000 r/min, as specified in the product details.

Q6: How does the Fixed Speed Basic Model Cylinder Type Magnetic Coupling provide overload protection?

A6: The Fixed Speed Basic Model Cylinder Type Magnetic Coupling provides overload protection by utilizing the magnetic field interaction between the copper conductor and the permanent magnets. When an overload condition occurs, the magnetic coupling can slip, preventing damage to the connected equipment.

Q7: What are the benefits of the copper conductor design in the cylinder magnetic coupling?

A7: The copper conductor design in the cylinder magnetic coupling maximizes the induction of magnetic fields. This design ensures efficient torque transmission across the air gap, contributing to the overall performance and reliability of the coupling.

Q8: How does the Fixed Speed Basic Model Cylinder Type Magnetic Coupling minimize electromagnetic interference (EMI)?

A8: The Fixed Speed Basic Model Cylinder Type Magnetic Coupling is designed to minimize electromagnetic interference (EMI). The magnetic flux level is kept lower than that of the associated motor, ensuring that the coupling does not interfere with other electrical systems.

Reviews

There are no reviews yet.